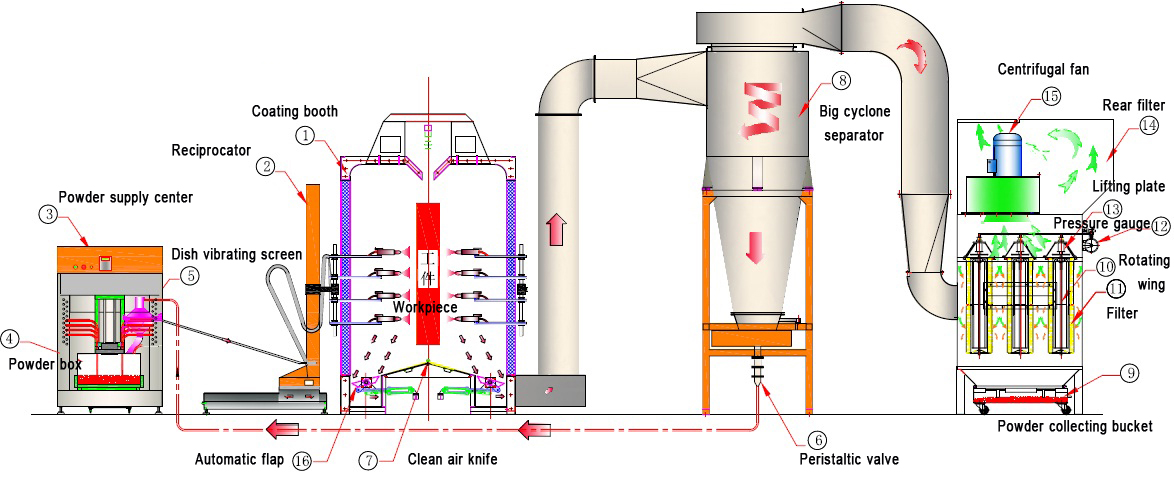

The Maintaince of Fast Automatic Color Change Powder Coating Booth

Clean up the accumulated powder in the powder coating booth every day (even without changing color), to prevent powder (accumulated for a long time) from solidifying on the powder coating booth inner plate.

Check the bottom of the powder coating booth “airflow pulse floor cleaning device” whether the air hole is blocked, clean the blocking air hole up in time , and control the cleaning pressure between 2-4bar.

2.Fast Automatic Color Change Equipment Separator

Clean up the powder in the cyclone every day (even without changing color), otherwise the powder will be solidified on the inner wall of the cyclone because of high speed rotation, which will lead to decrease the cyclone separation efficiency; check screen mesh and clean up the powder in it, change the damaged screen mesh in time; clean up the piled powder in recovery powder bucket to prevent powder agglomerating to affect the powder recovery and utilization; check whether the rise and down of screen mesh is normal, and whether the seal is well to prevent the low recovery efficiency due to the leakage of gas.

Clean up powder in the powder pump body every week to prevent recovery and utilization from affecting because powder accumulation and agglomeration.

Check the wear of powder pump and powder tube every six months and replace it in time if necessary.

Adjust the pressure of powder recovery to 2-4bar. If the powder recovery efficiency is too low, the air pressure should be increased appropriately, otherwise the air pressure should be decreased appropriately.

3.Two Level Recovery

Clean up the waste powder in the collection powder box every day, generally the weight of the waste powder is 3%–5% of the normal using powder weight; check the pressure difference range of pressure differential gauge, the normal range is between 1.0KPa – 2KPa, if it is over difference which indicates that the filter element is seriously blocked or the filter element cleaning device fails; the filter element cleaning pressure is set between the 4-4.5bar.

Check the powder accumulation situation on the filter element surface every week. If the powder accumulation is serious, it means that the filter element has been blocked or the filter cleaning device has failed.

Check whether the rotating wing work is normal every three months, whether the rise&fall disk on the rotating wing is cracked or damaged, and replace it if necessary.

Check and clean the bonding powder on the fan blade every year, check the vibration condition of the fan, and if it is necessary, take it down to do dynamic balance check.

4.Reciprocator

Open the side panel of reciprocator to check the tightness of the synchronous belt every week, adjust its tightness and clean the powder adhered to the guide rail in time.

Open the top hat and side plate of the reciprocator to check the wear condition of the belt pulley and bearing every month, and replace it in time if necessary.

5.Powder Box

Clean up the piled powder in powder box every week.

Check fluidizing plate fluidization situation and seal of fluidizing plate every three months, and replace it promptly if necessary.