Hanna Curing Oven Features:

Power Mode:CNG/LPG/Diesel/Electric

High Degree Of Safety

Limited Heat loss With Air Curtain

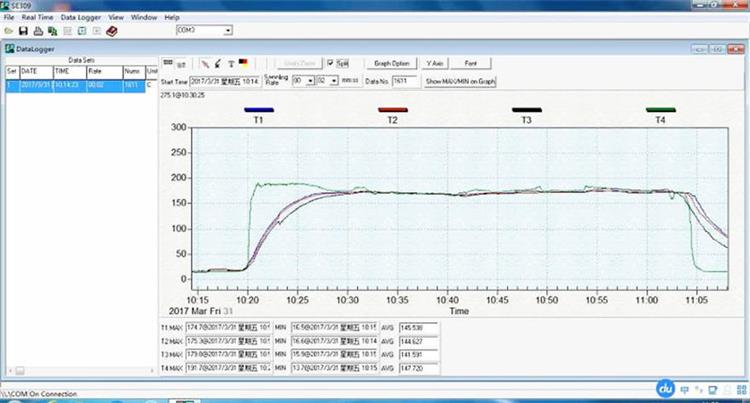

Uniform Temperature Within ±3℃

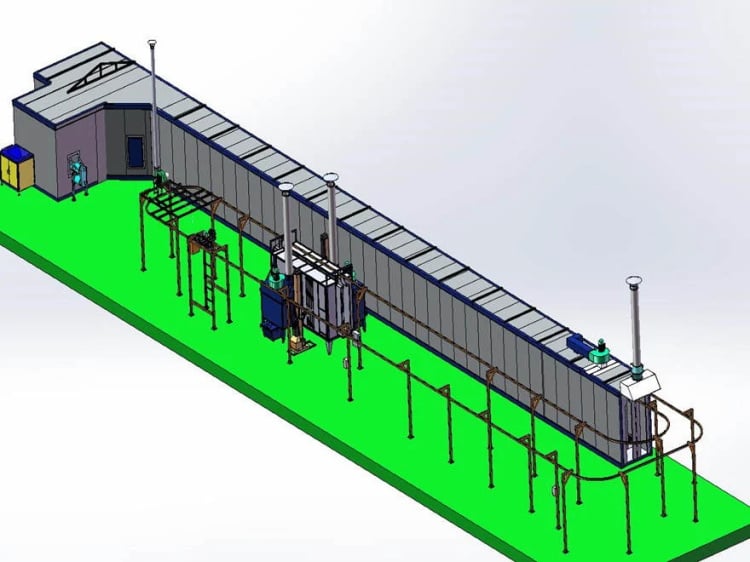

This structure get a significant design on wind curtain at both ends to efficiently prevent heat to dissipate out of oven. this is our patent.

High degree of Safety, the heat source that links to the curing tunnel, will automatically ventilates first, then ignites to eliminate safety hazards.

The structure of insulation board are made by technology like plug-in board,seamless docking, and thermal bridge transmission.

Fuel oil burner type, rightful design on thermal ventilation syetem make air circulation reach a perfect balance which keep furnace temperature stabe.

Gas burner type, heat 100% flow into the furnace, high efficiency, no waste.

the structure get perfectly workpiece.

Tunnel oven can be build up right on the flat ground, this work can be relatively cheaper than Camel Back Curing Oven, but reasonably weaker on thermal insulation because of heat convection. This design would be more suitable for long workpiece rather than wide one. if the opening of tunnel is too wide, the wind barrier will not be strong enough against heat convection, and that would make encourage heat loos, which slow down the oven heating up and increase power payment.

During the process of powder coating, curing oven is the one of the most important equipments in system line, and temperature uniformity would be an important index to influence the quality of powder coating.