Hanna Curing Oven Features:

Power Mode:CNG/LPG/Diesel/Electric

High Degree Of Safety

Limited Heat loss With Air Curtain

Uniform Temperature Within ±3℃

*Hanna box type curing oven features:

- Gives optimal design to meet your need.

- With our proud workmanship, Hanna solution would hit your budget and factory capacity requirements perfectly.

- We optimize your system on dimensions by completely going through your workpiece weight, size, shape and the other factors.

- Excellent durability and reliability

- Gives low-maintenance design

- Smart design make it to drive

- Easy to handle loading and unloading operations, provide solutions for cargo handling of any size and weight.

Description*Hanna box type curing oven features:

1. Gives optimal design to meet your need.

2. With our proud workmanship, Hanna solution would hit your budget and factory capacity requirements perfectly.

3. We optimize your system on dimensions by completely going through your workpiece weight, size, shape and the other factors.

4. Excellent durability and reliability

5. Gives low-maintenance design

6. Smart design make it to drive

7. Easy to handle loading and unloading operations, provide solutions for cargo handling of any size and weight.

Our powder coating oven can be optional in a variety of sizes from 6’T x 6’W to 12’T x 14’W , and the length go from 5′ to 50′. You show us your project info, Hanna would give you the answer, no matter how big your project is.

Gives significant double-panel design, door structure would go steel composition design by #16, 18 and 20 with rock wool insulation board plunged in, board density would not be selected less than 6#.

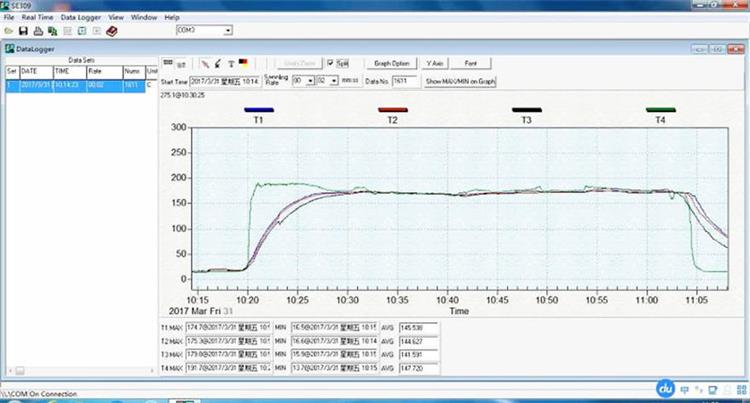

The heating device adjusts the performance according to the PID fuzzy logic controller of the control panel.

The heating unit uses a curved fan device to circulate air around through the powder coating oven to reduce fuel consumption

We also offer bearing components in wearing piece list, with significant feature against heat.