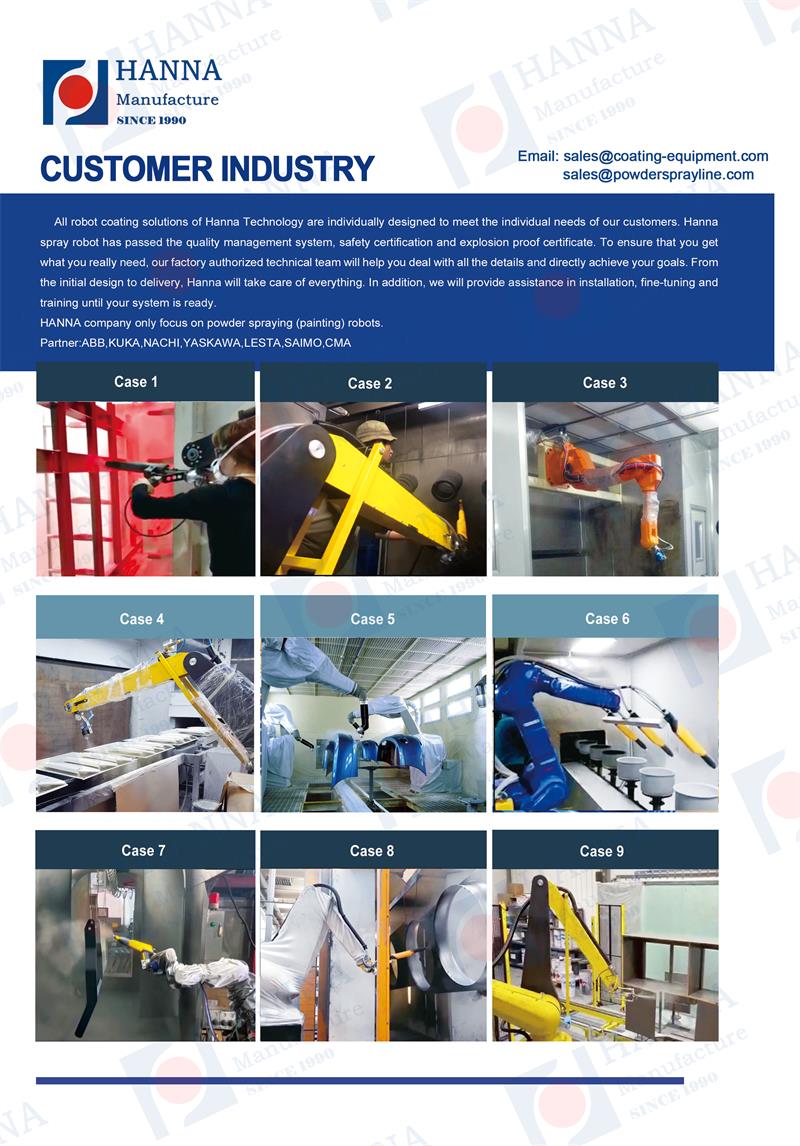

HANNA company only focus on powder spraying (painting) robots.

![]() 2.Drag teaching programming robot

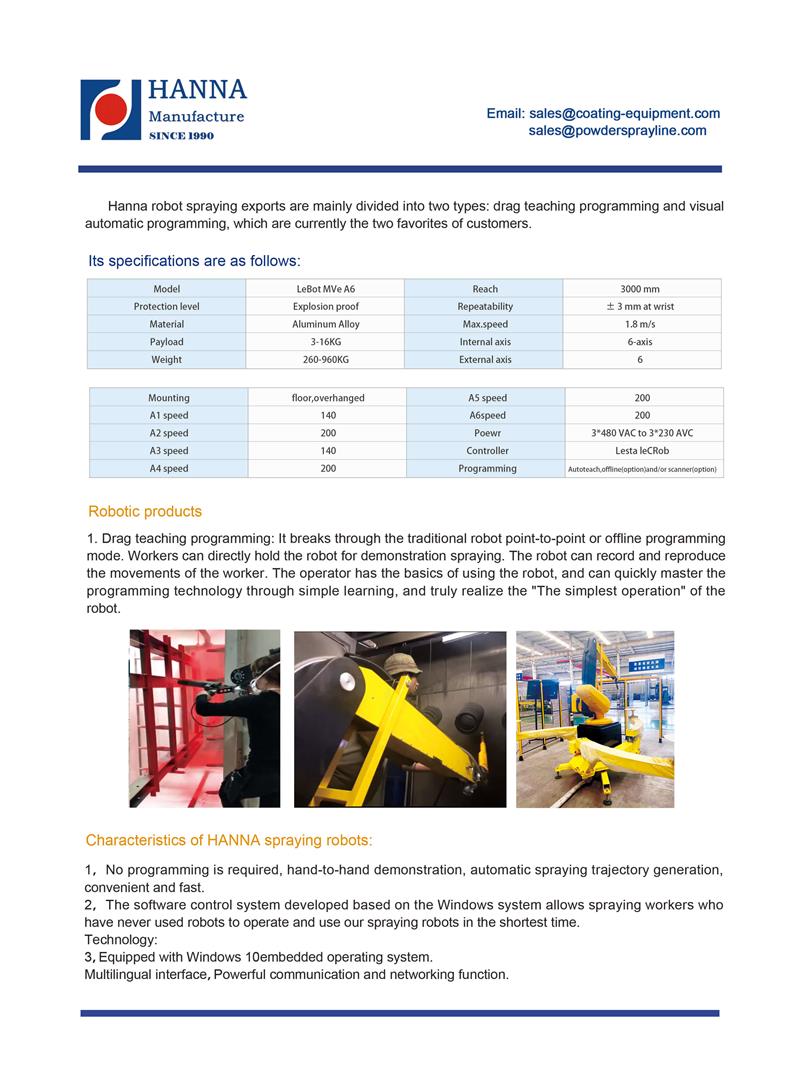

2.Drag teaching programming robot

Drag teaching programming: It breaks through the traditional robot point-to-point or offline programming mode. Workers can directly hold the robot for demonstration spraying. The robot can record and reproduce the movements of the worker. The operator has the basics of using the robot, and can quickly master the programming technology through simple learning, and truly realize the “The simplest operation” of the robot.

Characteristics of HANNA spraying robots:

1,No programming is required, hand-to-hand demonstration, automatic spraying trajectory generation, convenient and fast.

2,The software control system developed based on the Windows system allows spraying workers who have never used robots to operate and use our spraying robots in the shortest time.

Technology:

3,Equipped with Windows 10embedded operating system.

Multilingual interface

Powerful communication and networking functions

Stand field bus interface

Configurable digital and analogue I/O

15 “touch screen

Optional proportional valve for spray gun control

Built-in temperature and pressure monitoring and control system

Optional online support system

Standard Point to Point programming software

Online programming functions

Optional air conditioning unit

Optional gun control box

4,Auto-teach&Point to point programming

Programs retrieval based on PDF schedule or pictures

Online changes of painting parameters

Remote supervision of paint booth with IPCAM

External axis management

Motor &encoder test&programming

Interface for paint management

Multilingual

Profiled user access

alarms,warnings&events log

External database interface for MES or ERP

Remote control via mobile device

Fully integrated with LESTA Easy Panel and LESTA CAD light

5,Manage point to programming

Integrated with LeCRob Robot manager and K-Manager

Allows easy and quick creation of robot paths with manual or automatic points acquisitions

Manage lines ,splines,grid and parameters setting for each primitive.

Parameters which can be managed are speed,acceleration,distance from surface,grid steps and orientation,paint delay and advance on surface,flow, atomization and fan speed.

Via Video

Online Inquiry

If you want to custom made any powder coating line, Pls tell us the following specifications:

1.The material of your workpiece.

2.The size of your workpiece .

3.The weight of your workpiece.

4.The output of your workpiece (one day=8hours,one month=30days).

5.The heating power you prefer: electric, gas, diesel, or coal.

6.The size of your factory (length, width and height).

We could make the design according customer’s requirements. Pls contact with me and we will give you the quick reply.