Description

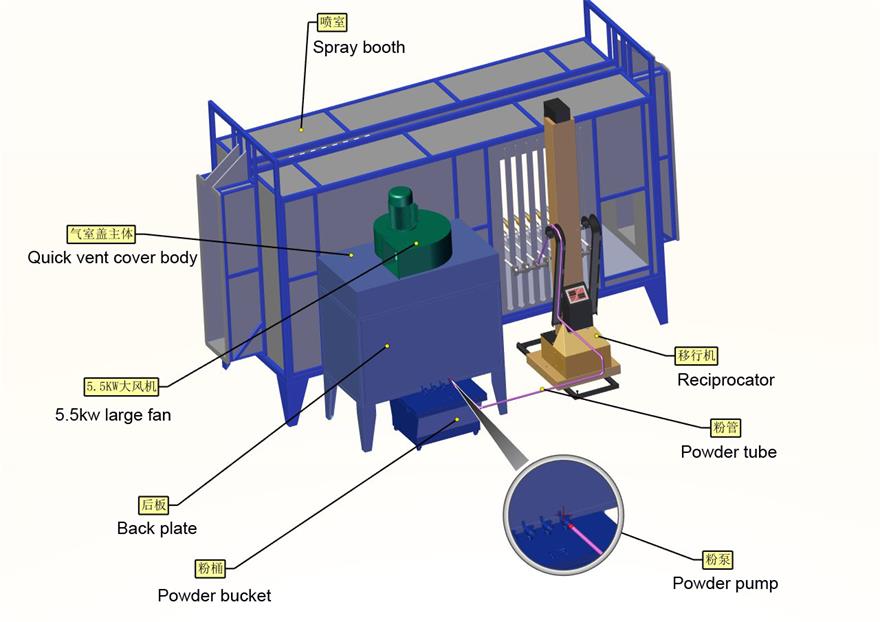

- No dust spill out.

- Color change process (10-15 minutes manual work).

- Smart design, and easy to handle.

- Safety and durability for sure.

- Outstanding appearance and fine workmanship

- Shorten your labor into one-man operation

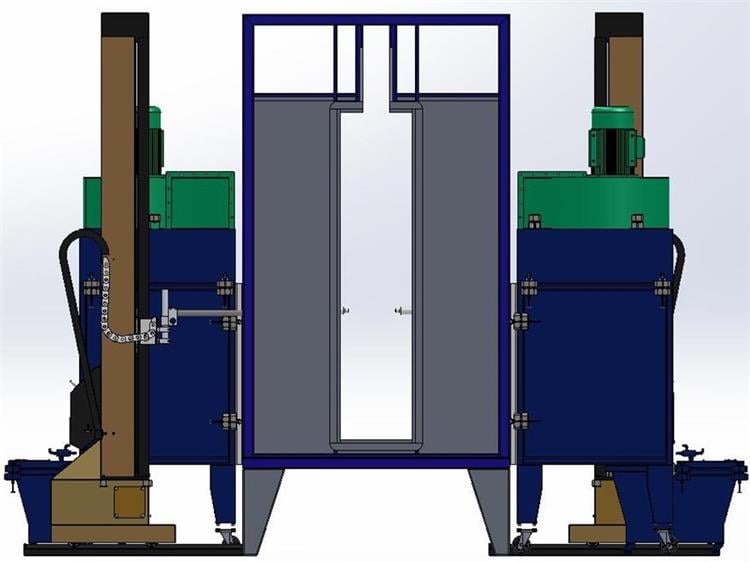

Hanna reciprocators:

- More spray guns run out of powder

The ZA07/08/15 reciprocating machine has high load capacity, can carry a large number of spray guns, and has high precision and reliability.

- Flexible horizontal longitudinal gun

The ZA07/08/15 reciprocator can be operated with short or long strokes and the gun can be placed horizontally or vertically.

- High load ZA15 reciprocator

The ZA15 can meet the weight of 100kg and is the weighted version of the ZA07 axial.

- Smooth operation design

AC motor drive, smooth gear conveyor and rugged design ensure low noise and high reliability during operation

- Simple maintenance and reliability

The ZA reciprocator requires only the least, simplest and fastest maintenance.

- Conveying chain speed automatic adjustment

The magic controller tracks the speed of the reciprocator and automatically adjusts to the optimum speed to perfectly match the bend for optimum spray results.

- Precision stroke control application

The stroke can be fine-tuned to the millimeter, and the powder application can be precisely adjusted to fit any size workpiece

- Continuous rate control for optimal application

Depending on the geometry of the object being sprayed, the pattern of the gun and the rate of transmission are continuously and accurately adjusted.

- Simple and powerful programming

OptiMove can store up to 250 trips and rates of program data and can be optimized for your application needs

- Advanced local programming

You can easily set different strokes or speeds in different parts of the program, making it ideal for complex and challenging application needs.

[/vc_c olumn_text]

Online Inquiry

If you want to custom made any powder coating line, Pls tell us the following specifications:

1.The material of your workpiece.

2.The size of your workpiece .

3.The weight of your workpiece.

4.The output of your workpiece (one day=8hours,one month=30days).

5.The heating power you prefer: electric, gas, diesel, or coal.

6.The size of your factory (length, width and height).

We could make the design according customer’s requirements. Pls contact with me and we will give you the quick reply.