Hanna powder coating equipment adopts the internationally recognized large cyclone recovery system, the powder recovery rate is as high as 99.2%, which ensures no dust spillover spillover out of the workshop, and the special fast color changing and supplying center, only 10-15 minutes to change the powder.

The electrostatic powder coating equipment spray indoor,powder coating gun in front of the implementation, in the air pressure spray powder with static electricity flying to the sprayed workpiece, 30 – 40% powder adsorbed on the surface of the workpiece under the action of electrostatic ,finishing workpiece surface coverage. 60 – 70% of the powder in the air is recycled by air suction cyclone recovery machine, powder flow in the cyclone barrel rotate quickly, complete separation from air and powder under the action of centrifugal force, the powder along the barrel wall fall into the bottom of the ash bucket, the air from the middle out.

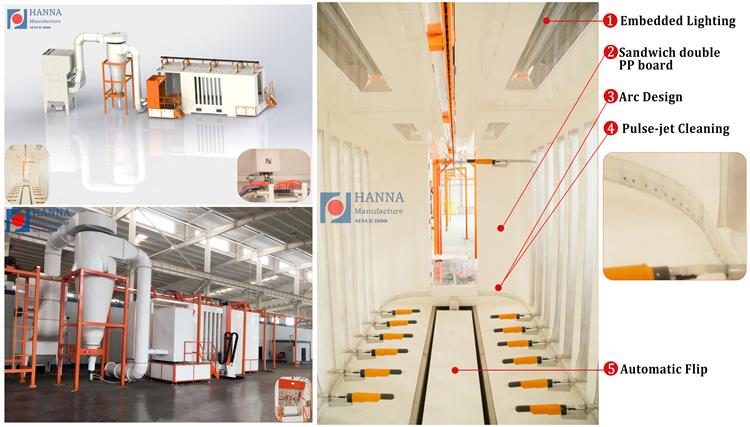

Recovery working principle of the powder coating booth:

The working state, the centrifugal fan pulverized the air out of the powder room through a filter element ,an extrovert air flow is formed at the nozzle of the spray chamber, the air flow can ensure the flying powder will not overflow; due to the filter element exists, only the air can pass through a discharge fan, the powder will be blocked by the filter element, staying in the powder coating room. When working for a long time, due to the powder accumulated in the surface of the filter element, which makes it blocked, causing recovery effect of the recovery system is reduced, so installing “pulse clean system” automatically clean powder in the outer surface of the filter element to guarantee the smooth flow of the wind, so as to ensure the continuous powder coating process, maintain good recovery effect in the recovery system.

Design,drawing,illustration,commissioning,training,technical support,testing in any step from material supplier to goods deliver.

Hanna reciprocators:

1. More spray guns run out of powder

The ZA07/08/15 reciprocating machine has high load capacity, can carry a large number of spray guns, and has high precision and reliability.

2. Flexible horizontal longitudinal gun

The ZA07/08/15 reciprocator can be operated with short or long strokes and the gun can be placed horizontally or vertically.

3. High load ZA15 reciprocator

The ZA15 can meet the weight of 100kg and is the weighted version of the ZA07 axial.

4. Smooth operation design

AC motor drive, smooth gear conveyor and rugged design ensure low noise and high reliability during operation

5. Simple maintenance and reliability

The ZA reciprocator requires only the least, simplest and fastest maintenance.

6. Conveying chain speed automatic adjustment

The magic controller tracks the speed of the reciprocator and automatically adjusts to the optimum speed to perfectly match the bend for optimum spray results.

7. Precision stroke control application

The stroke can be fine-tuned to the millimeter, and the powder application can be precisely adjusted to fit any size workpiece

8. Continuous rate control for optimal application

Depending on the geometry of the object being sprayed, the pattern of the gun and the rate of transmission are continuously and accurately adjusted.

9. Simple and powerful programming

OptiMove can store up to 250 trips and rates of program data and can be optimized for your application needs

10. Advanced local programming

You can easily set different strokes or speeds in different parts of the program, making it ideal for complex and challenging application needs.