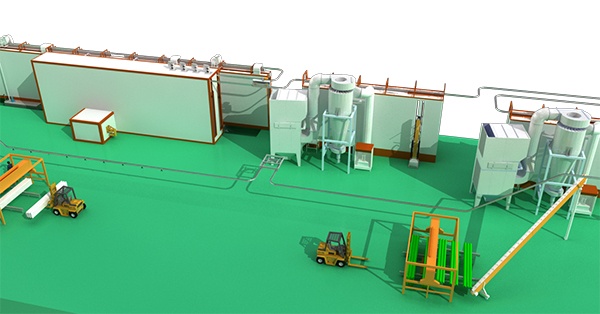

Time spent in the oven is determined by the coating suppliers, who specify the required time at a given temperature to thoroughly cure the coated product. However, line speed, product window size, hanging spacing and product weight/conveyor weight must be defined prior to designing a cure oven.

Line Speed.

Assume a production rate of 600 parts per hour.

Assume each carrier holds two parts.

Required number of carriers per hour 600 ¸ 2 = 300 carriers per min.

Required number of carriers per min 300 ¸ 60 = 5 carriers per min.

Assume a carrier spacing of 1 Mtr

Five carriers per min × 1Mtr = 5 Mtr/min.

Example:

Ware centers × required production = conveyor length

0.6 × 1,000/shift = 600 Mtr/shift

Conveyor length, production time = conveyor speed

600 Mtr per shift/8 hrs per shift divided by75Mtr per hr/60 min per hr = 1.25 Mtr/min

To allow for variation in production requirements, it is advisable to set a maximum speed of about two times that calculation. A variable speed with a speed range of about 3:1 is the most common.

Moving product/conveyor load weight.

Product Ware Weight

Unit Hanger (carrier weight)

Conveyor Weight

Design Conveyor Speed

Conveyor speed × 60/Ware center = units/hr

Units hr × Ware weight = _____kg ware/hr

Unit hanger weight × Units/hr = _____kg hanger/hr

Conveyor weight/ft (in lbs) × conveyor speed Mtr/min × 60 = kg conveyor/hr.