Toward Intelligent Factory: The Innovation Road of Powder Coating Automated Production Line

With the arrival of Industry 4.0, intelligent manufacturing has become the mainstream trend of manufacturing industry, and powder coating automated production line, as an indispensable part of modern industrial production, is also undergoing innovation and upgrading to meet the market demand and improve production efficiency.

This article will discuss the innovation and future development trend of powder coating automated production line.

Automation equipment and intelligent factory

- automated coating robots: modern powder coating production lines are generally equipped with automated coating robots, through advanced sensors and control systems, to realize the automatic control and monitoring of the coating process, greatly improving the production efficiency and coating quality. 2. automated conveyor systems: automated conveyor systems are widely used in powder coating production lines, to meet the market demand and improve the quality of the coating process.

- Automated Conveyor System: The automated conveyor system carries out automated and continuous conveying of workpieces from cleaning, pre-treatment to spraying and curing, reducing manual intervention and process interruption, and improving the stability and continuity of the production line.

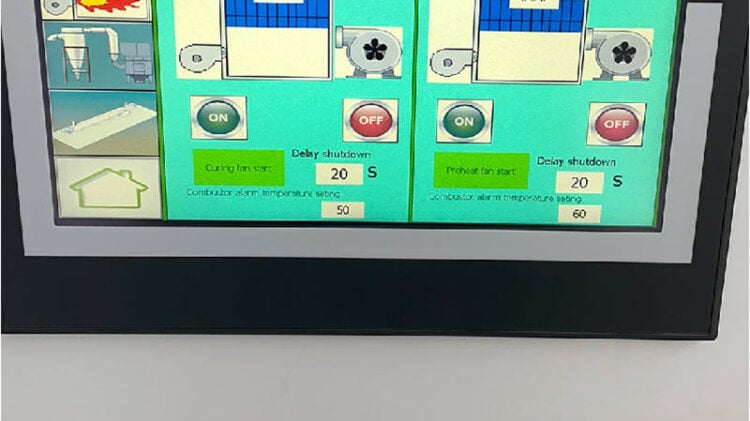

- Intelligent data management: The powder coating automated production line adopts an intelligent data management system to realize real-time monitoring and data analysis of the production process, which helps the enterprise to discover problems and make adjustments in time, and improves production efficiency and product quality.

Advanced technology-driven innovation

- Artificial Intelligence Technology: The application of artificial intelligence technology will make the powder coating production line more intelligent and adaptive, and the machine learning algorithm can continuously optimize the coating process according to the production data to improve the intelligent level of the production line.

- Internet of Things (IoT) technology: The application of IoT technology realizes the interconnection of information and intelligent management between production equipment, and helps enterprises to realize fault prevention and production plan optimization through remote monitoring and equipment status prediction.

- virtual reality technology: the application of virtual reality technology makes the design and optimization of the production line more intuitive and efficient, through virtual simulation technology can be found in advance of the design defects and optimization of the production process, reducing the production line construction and operation costs.

Environmental protection, energy saving and sustainable development

- application of energy-saving and environmental protection technology: the powder coating automated production line adopts high-efficiency coating equipment and environmentally friendly coatings, which reduces energy consumption and environmental pollution and realizes energy-saving and environmental protection in the production process.

- recycling technology: the application of recycling technology realizes the resourceful use of waste materials and waste water, reduces the waste of resources and environmental load, and realizes the sustainable development of the production process.

Conclusion

The road of innovation of powder coating automated production line is full of challenges and opportunities. With the continuous innovation and application of advanced technology, it is believed that the powder coating automated production line will show a broader application prospect in the future development, and make a greater contribution to the intelligent and sustainable development of industrial production.