What is the difference of water-spinning wet spray paint booths?

Water-rotation spray paint room, also known as Wen’s spray paint room, is designed to solve the problem of frequent blockage of the water circulation system of the original water-rotation spray paint room.

The working principle of water-rotation spray paint room

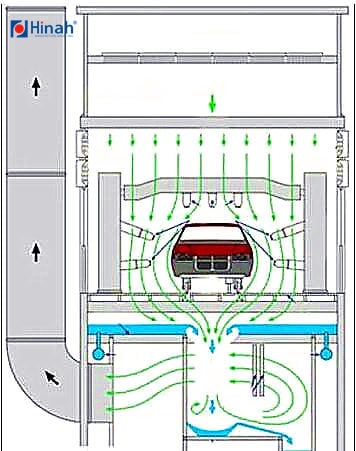

The outdoor air enters the spray painting room after being purified by the filter material at the top of the spray painting room, and flows around the workpiece and the operator from top to bottom.

Then, the exhaust air containing particles produced in the work is quickly led to the water spinner below the floor grille because of the outdoor exhaust fan.

The water overflowing from the overflow tray to the water cyclone is atomized under the action of high-speed airflow and then fully mixed with the airflow into the water cyclone, which will clean most of the particulate matter into the water.

Advantages and differences of water-spinning spray booths

Hanna’s water spinning spray booth system has many advantages.

- 1, Water-rotating spray booths are widely used for spraying large and medium-sized workpieces transported by suspended and platform vehicles, such as automobiles, water pumps, containers, transformers, sheet metal structural parts, etc.

- 2、 The purification rate of the apparatus reaches more than 98%.

- 3、 The equipment has no water pump, the pipeline is not easy to be blocked, and the maintenance is convenient.

- 4、 When painting in winter, the temperature of air supply is constant, the airflow in the room is stable, and the paint mist is not easy to fly.

The operation process of water-spinning spraying room.

Start the air conditioning air supply system, the fresh air is filtered and sent to the static pressure chamber at the top of the water-spinning paint spraying room through the dynamic pressure duct, and then sent into the chamber uniformly with cross-sectional wind speed after the equal-flow regulator and filter layer, from top to bottom, so that the workpiece is in the set equal-flow wind speed, the over-sprayed splash paint mist is pressed by the airflow into the liquid cyclone paint mist purification system in the paint spraying room.

The water is atomized under the impact of high-speed airflow and fully mixed with waste paint mist, so that the paint mist is attracted to the water and brought to the reservoir, the air containing water is separated by gas and water, clean air is sent to the atmosphere by the exhaust system, and the purification rate of paint mist reaches more than 98%; and the water containing paint mist flows into the circulating pool.

Through coagulation purification (water regularly added special coagulant) by the circulation pump sent to the spray paint room recycling, floating paint slag regularly fished out after centralized treatment.

The characteristics of the water-rotating spray paint room.

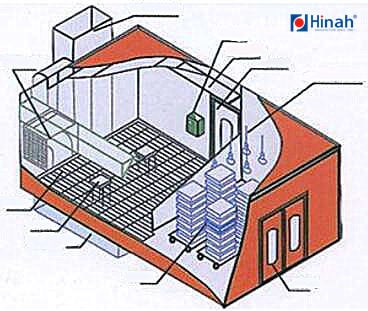

Water-rotation spray paint room is an important equipment to control the quality of product painting. Water-rotation spray paint room consists of chamber, air supply device, paint mist filtering device

- 1, The role of water-rotation spray paint room is to limit the paint mist in the spraying process to a certain area for filtering and processing.

- 2, The working environment made by the water-rotation spray paint room can meet the air environment requirements during the painting operation.

- 3、 Protect the operator’s body.

- 4、 To control the waste emission from the painting operation.

- 5、 Protect the environment from pollution, etc.

- 6、 It is composed of four parts, namely, air extraction device and air ventilator.