1, The advanced oil removal and demulsification technology is used to realize synchronous processing and synchronous utilization, so as to avoid the two pollution of the workpiece. So that the aluminum profile can get better quality and extend the service life of the product.

2,According to the maximum pressure of the water pump, the distance between the splash of the water mist and the time of the water drop from the surface of the workpiece are accurately designed, and the ventilation system is properly arranged to eliminate the problem of the series of liquid.

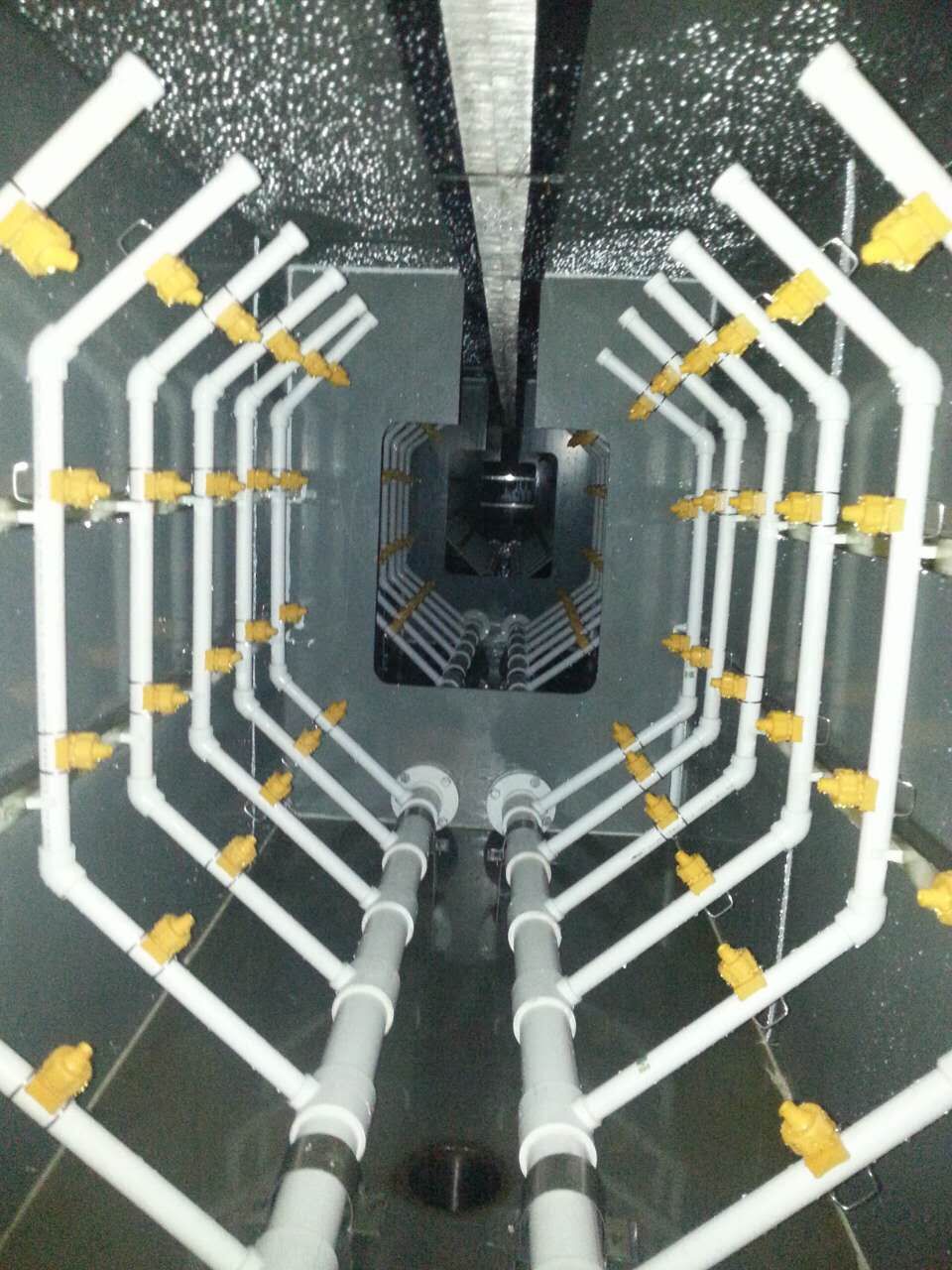

3,It can reasonably control the cleaning time, the temperature of the constant temperature degreasing fluid and the pressure and angle of the nozzle, so that the surface of the aluminum profile is cleaned more cleanly.

4, Automatic aluminum profile spraying equipment, cleaning is more clean and thorough, not affected by human factors, and save 2-3 workers, work efficiency increased by 30%;

4, Automatic aluminum profile spraying equipment, cleaning is more clean and thorough, not affected by human factors, and save 2-3 workers, work efficiency increased by 30%;

5,The surface of the cleaned aluminum is stable and uniform, with clean and smooth surface, high gloss and strong powder adhesion.

The pre treatment of the spraying equipment of the aluminum profile spraying equipment is not online before treatment, and the internal corrosion treatment is done inside, and the surface of the aluminum profile is degreased and degreased by environmental protection water, so that the surface cleaning of the aluminum material is more clean.