For spraying equipment, planning is not only to meet the needs of users, and the initiative of such questions, but also to consider the following guidelines.

Safety criteria

It is necessary to follow the safety planning criteria for spraying equipment and spraying conveyor lines, which mainly include the strength and rigidity of the equipment to meet the fire protection standards, electricity safety requirements, mechanical damage protection and safety protection measures.

Economic criteria

Considering the economic benefits of painting, the first choice is to select the equipment with moderate cost, high painting efficiency, high paint utilization rate and high qualified rate. The choice of equipment structure is technically ahead and economically reasonable. Under the premise of ensuring the completion of production tasks and the quality of commodities, we should reduce costs and improve economic efficiency. The selected equipment and its construction methods should be suitable for the commodities and workpieces, production value and the selected painting skills, and make full use of the existing active spraying machine and production conditions in the factory.

Environmental protection guidelines

To improve the understanding of environmental protection, we should start from the source of skills, that is, from the paint and painting skills, select non-toxic or low-toxic paint; initiate the selection of cleaning production; should be easy to operate, conducive to the health of operators and environmental protection to consider the appropriate active paint spraying machine; in the production process, but all can spill harmful gases or It is necessary to set up effective partial heat exhaust and exhaust gas heat energy in dust process and spraying equipment to make full use of heat energy.

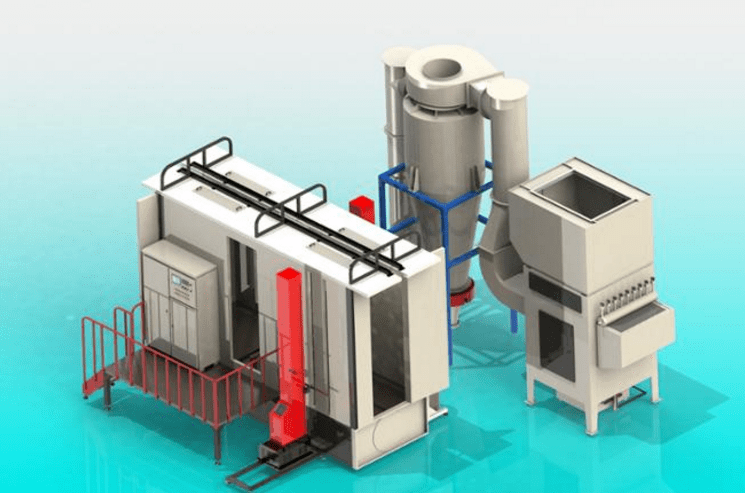

The spraying equipment has universal standard equipment and non-standard equipment. The selection of equipment construction methods, the determination of standards and the calculation of their quantities should be determined according to the requirements of commodity skills, production scale, output value, the shape and size of painting workpieces, painting methods and production skills.

Hanna Technology Co., Ltd., a professional custom powder coating equipment, designed for you to help you improve production and improve quality.

we web:www.powderspraymachine.com

www.coating-equipment.com

whtasapp:+8618632138668

email:sales@powderspraymachine.com