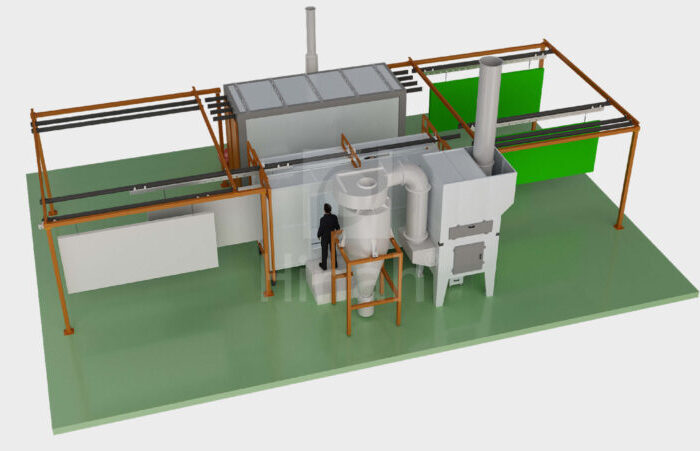

Structural features of the cyclone recovery in the powder spraying powder workshop

The recovery cabinet is mainly divided into six parts, namely: powder spraying room exhaust pipe, primary cyclone cabinet, secondary pulse filter cabinet, fan exhaust/exhaust pipe, fan system and electric control cabinet.

A.spraying room exhaust pipe

The spraying room exhaust pipe is the exhaust pipe connecting the powder spraying room and the recycling equipment. It adopts flange connection structure, using δ1.5mm steel plate seal welding, and external spraying or painting treatment. This construction ensures that the powder containing gas can pass smoothly through the duct from the spray chamber into the recovery equipment for effective recovery. This ensures that the ducts are sealed and corrosion resistant, preventing powder leakage and loss of airflow.

B.primary cyclone cabinet

The primary cyclone cabinet is a large cyclone powder recovery and treatment system with an all-steel structural design and an overall plastic spraying treatment. The middle part is equipped with a cyclone cylinder and the upper part is a cyclone box, which is equipped with several inspection and cleaning windows and is also equipped with a powder self-cleaning device. The lower part is a primary powder recovery box, which is connected by a lock for easy disassembly and assembly. The materials chosen include 80 x 80 square pass, angle steel and δ1 to 1.5mm steel plate. This allows for efficient powder separation and recovery, easy inspection and cleaning of powder residues, improved recovery rate and service life.

C.second pulse filtration cabinet

The second pulse filtration cabinet is a kind of pulse back-blowing cartridge powder recovery and processing system, which is also designed with all-steel structure and overall plastic spraying treatment. Its upper part is the pulse box, which is equipped with a pulse gas tank, 12 groups of pulse valves and solenoid valves, as well as the related circuit and air circuit structure. The middle part is the filter box with 24 sets of built-in rotary cartridges for excellent filtration performance and long life. The bottom part is the secondary powder recovery box, which is designed with a side-opening structure for ease of use. The materials chosen include 40 x 40 square pass, angle steel and δ1 to 2mm steel plate and related accessories. This allows for further filtration and recovery of the fine powder that the primary cyclone cabinet fails to separate, using pulse back-blowing technology to clean the adhering powder on the surface of the cartridge at regular intervals to ensure filtration efficiency and air quality.

D.fan suction duct

The fan suction duct is the suction duct connecting the secondary pulse filtration cabinet to the fan system. The clean air filtered by the filter cartridge enters the fan system through the duct. It adopts flange connection structure, using δ1.5mm steel plate sealing welding, and surface spraying or painting treatment. This ensures smooth air circulation and prevents air pollution and noise disturbance.

E.fan system

The fan system consists of a large 4-72 centrifugal fan with a power of 37.0 KW and an air volume of 23,000 m3/h. In addition, the fan system is equipped with a fan silencing system, which allows the fans to be controlled in a star to triangular pattern to further reduce noise. This provides powerful suction and a steady airflow rate for efficient powder recovery and air discharge with reduced noise pollution.

F.electronic control cabinet

The electronic control cabinet is the control centre of the Cyclone II powder recovery cabinet. It is automatically controlled by a microcomputer chip with program flow command function and uses famous brand electronic control components to achieve automatic control of fan, pulse and ash cleaning functions. The electronic control cabinet plays a key control role in the entire powder recovery system, ensuring stable operation and efficient working of the system. This enables intelligent management and operation of the entire recovery system, improving efficiency and safety.