Powder spraying equipment assembly line is generally composed of pre-processing equipment, powder spraying equipment, drying tunnel and chain, and electronic control equipment.

The pretreatment electrophoresis process is the process with the longest equipment and the most control parameters in the painting workshop. Its effect directly affects the service life and effect of the workpiece; it is a very important part of the entire painting process.

The main technological process of pretreatment electrophoresis line includes pre-degreasing, degreasing, water washing, surface conditioning, phosphating, washing after phosphating, electrophoresis, and ultrafiltration washing with pure water.

The purpose of the pre-treatment is to remove the oil stain on the surface of the workpiece and form a dense phosphating film layer to improve the corrosion protection of the metal body of the coating; the electrophoretic coating enhances the corrosion resistance of the workpiece.

The entire process of the pretreatment line involves chemical and electrochemical reactions. It has the characteristics of high degree of automation, little manual work participation, and environmental protection. It has become the first choice for modern workpiece coating.

Phosphating treatment can significantly improve the corrosion resistance and adhesion of the coating. Phosphating film formation refers to a certain degree of corrosion reaction on the metal surface under appropriate control conditions. As a result, a metal compound film layer is formed on the metal surface .

As mentioned above, in order to obtain a complete and fine phosphating film, the premise is that under certain conditions and strict control of the front road and the road parameters and excellent on-site management level can be guaranteed.

The most common problems of phosphating reaction are phosphating yellow rust, twill, phosphating hair, etc.

The process flow of the pretreatment line is pre-washing → pre-degreasing → degreasing → one-washing → two-washing → surface adjustment → phosphating → three-washing → pure washing → clean spraying.

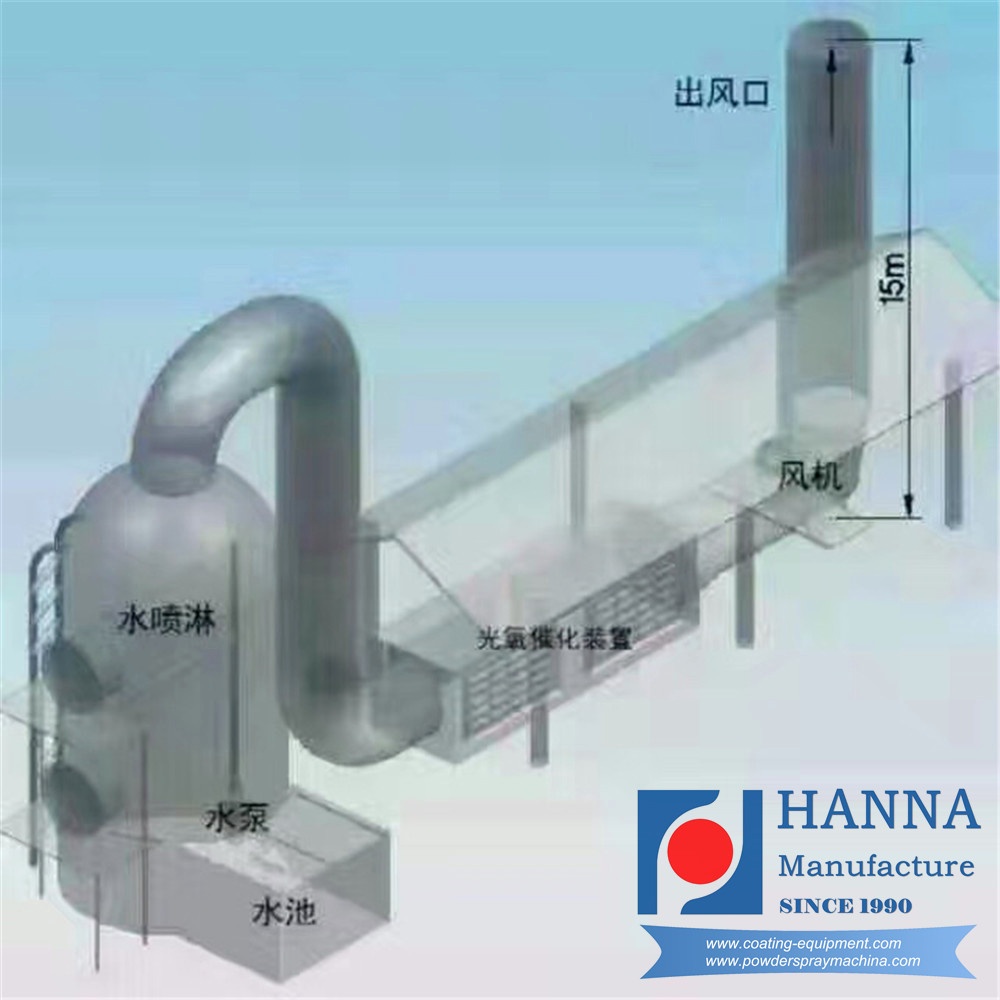

Fans are installed on the top of the degreasing tank, surface conditioning and phosphating tank.

It is recommended to improve the exhaust air supply equipment of the pretreatment of the powder spraying equipment.

After the exhaust air supply device is added, the entire pre-treatment will be formed into a low-pressure state, that is, the direction of the workpiece into the wire body and the two directions of the gas are drawn from the degreasing exhaust air.

The other gas from the opposite direction of the workpiece entry and the two directions of regulation and regulation is drawn from the exhaust air of the phosphating.

In general, the air supply in the table below is natural air supply, and air supply equipment can also be installed.

However, the power of the air supply equipment installed is less than the power of the air exhaust equipment at the degreasing and phosphating sites.

Only in this way will the entire system of the pretreatment of the spraying equipment become a low-pressure state, reducing the high-temperature, high-pressure and high-humidity conditions of the pre-treatment, thereby reducing the occurrence of rusting of the workpiece in the environment of high temperature, high humidity and high pressure.

The improvement of tank circulation can be accomplished by regular tank inversion and acid cleaning phosphating slag treatment, so that the internal circulation of the tank maintains a good effect.

Paying attention to these points can better carry out painting work and bring more economic benefits to the company.

Hanna Technology has been focusing on the design and manufacture of powder spray lines for more than ten years. With rich experience and perfect pre-sales and after-sales services, the products have been sold to more than 200 countries and regions at home and abroad. It is not our goal to have products all over the world. , But our driving force!