The production of powder coating booth is a key process in the production of spraying, and the key to the surface quality of the sprayed workpiece lies in the control of the process parameters. The amount of powder and atomized air are the two key technical indicators.

Before the formal spraying of powder, you can try spraying several times, when you can observe the size of the amount of powder and the uniformity of powder distribution at both ends of the powder coating booth. At this time, the powder in the distance from the end of the gun within 10cm-15cm part of the straight line running, outside the part is in the form of atomized powder, adsorbed on the surface of the workpiece is actually this atomized effect of the powder, whether the existence of this atomized effect of the powder is used as a standard to control the distance between the gun and the profile. In addition to the process parameters, some of the necessary small links should also be noted.

1、Location of the spray gun

The gun should maintain a certain tilt, biased toward the direction of the workpiece running, the gun in the arrangement to maintain vertical parallelism, the end part to maintain in a straight line, there should be no overlap between the guns, the location of the upper and lower guns to the powder to cover all the workpiece is appropriate.

2, fluidized air pressure control

The role of fluidized bed is to use the role of airflow, so that the powder to form a proper fluidization state, feel similar to the state of liquid flow, detect fluidization to reach a full state, the simplest operation is: when stirring the powder by hand or stick, do not feel the presence of resistance. Fluidization facilitates powder inhalation conduit, under the action of accelerating wind, the effect of atomization, insufficient pressure or too much pressure will cause inadequate fluidization generated.

3、Recycling and reuse of powder

Powder adsorbed on the surface of the profile only accounts for about 1/3 of all gun powder, scattered in the powder coating booth more powder, recycled powder must be mixed with the new added powder in the appropriate proportion, the effect is better, so the powder should be recycled and reused in a timely manner.

4, the closed nature of the powder coating booth

The powder is easily polluted by the suspended matter of the outside air, and the surface of the profile is prone to flocculation or shrinkage after spraying powder, which affects the flatness of the surface of the profile after baking, so the spray room should take closed measures to prevent the invasion of pollutants.

5、The residual powder in the air pipe should be cleaned and cleansed in time, and if it is not used for a long time, it will be easy to agglomerate and the powder will easily produce the phenomenon of spitting powder, which will affect the spraying effect.

6, spare powder bucket

To be used when changing powder, can effectively improve labor efficiency, spare powder bucket dust, moisture and other maintenance work must be done to ensure the quality of the remaining powder in the bucket.

7、In addition, the work of powder should also be paid attention to

Although the technical parameters in the production of normal before the debugging has been completed, but also from time to time through the supplemental powder window on the workpiece for uninterrupted monitoring, found that the powder shallow and not adsorbed powder place in time to supplement the powder. As the manual rubbing gun spraying powder volume is larger than the automatic gun, so the manual rubbing gun with hand swing speed can be appropriately accelerated.

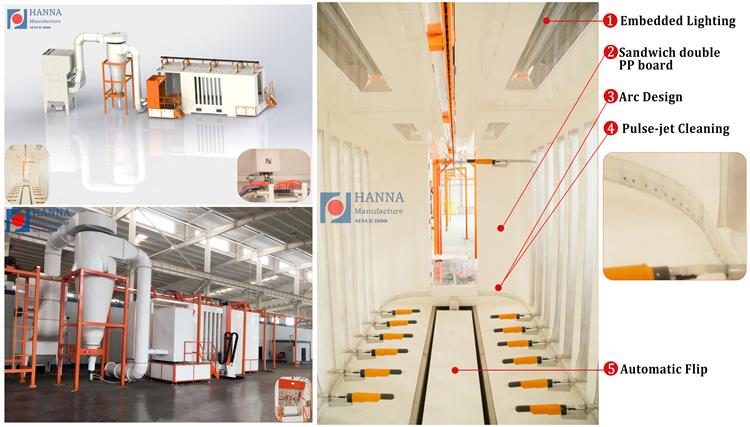

Fast Color Change powder coating Booth