The inside of the automatic spray gun has a pneumatic piston mechanism with a stainless steel needle above the piston and a set of high tension springs behind the piston. When the compressed air stops supplying, the spring pushes the piston and the needle forward. When the needle and the nozzle are closely matched with high precision to block the passage of the liquid, when the compressed air starts to be supplied, the pressure of the compressed air pushes the piston open, so that a gap is formed between the needle and the nozzle to allow the liquid to be ejected. The liquid after the ejection is then brought into contact with the atomizing air to produce an atomizing effect.

Japan Iwata WA-101 spray gun is a small automatic spray gun, suitable for small objects spraying, suitable for metal, toys, plastics, furniture, handicrafts, wood products and other spraying.

After the spray gun is used, spray it with the thinner of the sprayed paint until the spray coating channel is cleaned. Otherwise, the dry solid blockage of the gun will affect the normal use of the gun. Specific cleaning method; close the compressed air, remove the storage tank, pour the paint inside the paint into the storage tank, pour the paint in the tank into the container; pour about 1/4 volume of solvent into the storage tank Rinse, install the paint can, turn on the compressed air, repeat the rock and roll several times; remove the nozzle, wash it with solvent and install it; wipe the paint on the gun body.

When washing the spray gun, pay attention to the following points: use a soft brush when brushing, do not use metal brushes, do not use hard objects to smash, scrape, prevent wear nozzles, change the shape of the jet; avoid the spray gun directly in the solvent, Anti-residue paint attached to the machine and the lubricant on the gun can be wiped off with a soft cloth dampened with solvent; the knurled parts on the gun are adjusted by hand to avoid the use of pliers tools; regular needles and guns Lubricate the oil at the pin; apply light grease or Vaseline lubrication needle valve and needle valve spring regularly. Do not use silicon-containing oil.

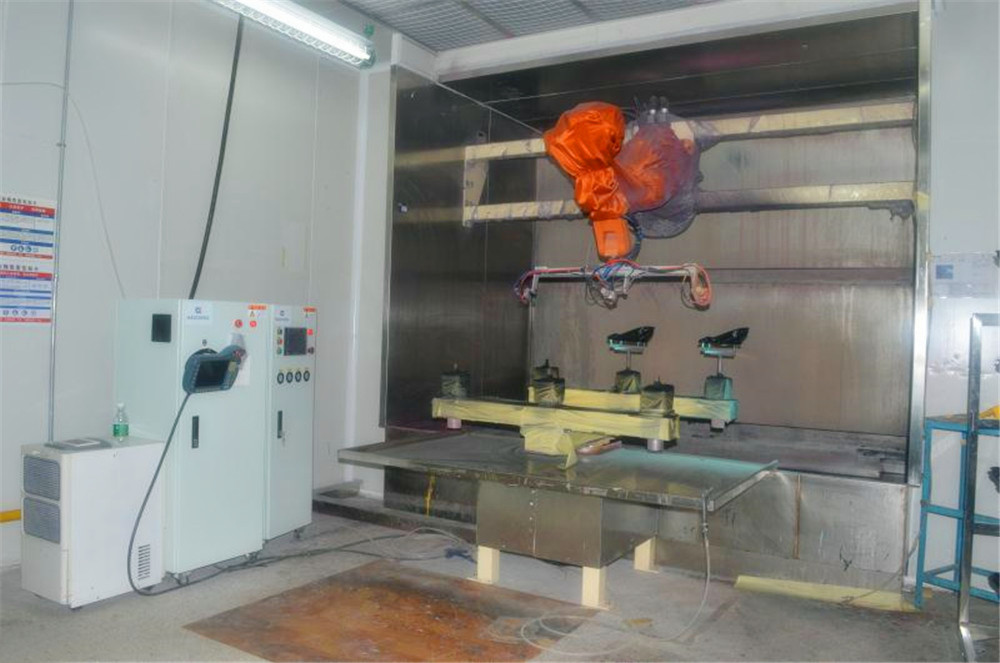

Spray booth seal

In order to make the air in the spray booth clean and dust-free, the doors and windows of the spray booth should be equipped with air purification and filtering devices. The 200-mesh silk cloth is usually installed on the doors and windows, so that the air entering the spray booth is filtered and dusted to achieve purification. purpose. In front of the workbench is a water curtain machine and an exhaust fan, which can make the flying paint mist generated during the spraying operation be discharged out of the room by the exhaust fan, keeping the indoor air fresh, which is beneficial to the health of the operator and prevents the flying paint. The mist splashes on the surface of the coated object after spraying, ensuring that the surface to be coated is smooth and smooth.

Hebei Hanna technology co ltd,

we web:www.powderspraymachine.com

www.coating-equipment.com

whatsapp:+8618632138668

email:sales@powderspraymachine.com