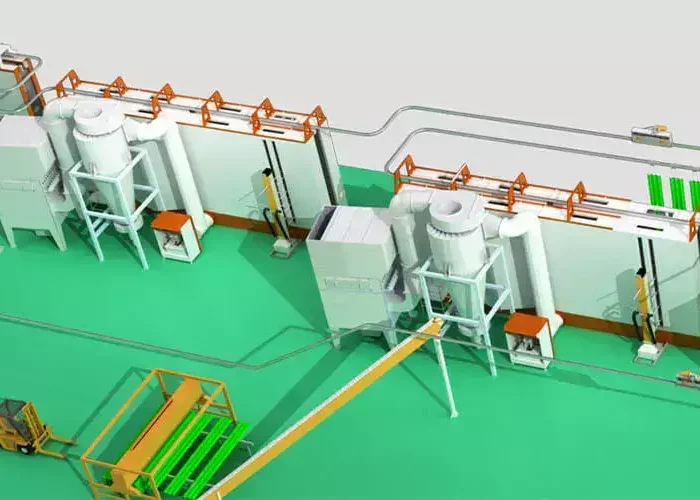

Doors and air curtains in the powder plant have an important role in powder escape that cannot be ignored

Powder escape is a common problem in the powder coating production process, and the doors and air curtains in the powder workshop have an important influence on powder escape.

In this paper, we will focus on the influence of the door and wind curtain on powder escape in the powder workshop, and discuss how to choose the right door and wind curtain to improve production efficiency and product quality.

I. The influence of the door on the powder escape

1. Airtightness

The airtightness of the door has an important impact on the powder escape. If the door is not sealed, the powder can easily escape from the powder room, resulting in waste and environmental pollution. Therefore, it is very necessary to choose the door with good air tightness.

2. Opening method

The way the door is opened will also affect the powder escape. Some doors need to be fully open to get in and out, which will lead to increased time for powder to escape; while other doors can be accessed through small doors or channels, reducing the chance of powder escaping.

3. Size and number

The size and number of doors on the powder escape also has an impact. If the door is too small or insufficient number, will cause congestion in and out of the personnel, will also increase the chances of powder escaping.

II. The impact of the wind curtain on the powder escape

1. Wind curtain type

In the powder workshop, the common type of wind curtain has air curtain and water curtain. Air curtain through the high-speed airflow will be separated from the air, so as to prevent the powder from escaping; and water curtain is the use of water curtain will filter the air, so as to prevent the effect of powder escaping. Therefore, in the choice of air curtain, should be based on the actual situation to choose the right type of air curtain.

2. Wind speed and air flow

Wind speed and air flow on the wind curtain to prevent the effect of powder escape has a direct impact. Usually, the greater the wind speed and air flow, the smaller the chance of powder escaping.

3. Installation position and quantity

The installation position and the number of air curtain will also affect its effect. When installing the air curtain, you should consider whether the location of the air curtain covers every corner of the powder room, and choose the appropriate number to achieve the best effect of preventing the powder from escaping.

III. Summary

In general, doors and air curtains play a very important role in the powder coating production process. Doors need to be airtight and open in the right way, size and number, while air curtains need to be of the right type, speed and flow rate, and installed in the right location and number for the situation. The following are some recommendations for selecting doors and air curtains:

- 1. When choosing a door, you should consider air tightness, opening method, size and number. In general, the door should have good airtightness and can be designed with double doors to reduce the chance of powder escaping. The door should be opened in a suitable way to choose a small door or channel, to avoid completely open the door when the powder escapes the opportunity to increase. The size and number of doors should also be selected according to the actual situation, in order to avoid congestion when people enter and exit.

- 2. When choosing the air curtain, you should consider the type of air curtain, wind speed and air flow, installation location and quantity. Air curtain can be separated by high-speed airflow to prevent the powder from escaping; and water curtain can be used to filter the air to prevent the powder from escaping. In the choice of air curtain type, should be selected according to the actual situation. Wind speed and air flow should be large enough to achieve the best effect of preventing the powder from escaping. Installation location and number should also be selected according to the actual situation, in order to cover every corner of the powder room to avoid powder escape. 3.

- 3. When using doors and air curtains, they should be regularly maintained and cleaned to keep them functioning properly. The sealing of the door and the filtering effect of the air curtain need to be checked and replaced frequently to ensure their effectiveness.

To sum up, the door and air curtain in the powder workshop have an important influence on the powder escape. When choosing doors and air curtains, they should be selected according to the actual situation and regularly maintained and cleaned to achieve the best effect of preventing powder from escaping. This will not only improve production efficiency and product quality, but also reduce waste and environmental pollution to achieve the goal of sustainable development.