Hot Sales Smooth! Dip tank powder coating line helps wire fencing mesh get a new lease of life

As a common and important fencing material, wire fencing mesh plays a key role in landscaping, farmland protection, industrial parks and other fields.

However, long-term exposure to the environment, wire fences are often susceptible to oxidation, corrosion and other factors, thus shortening its service life and affecting the appearance of the aesthetic.

In order to solve this problem, the dip tank powder coating line came into being and is becoming a hot product in the market with its excellent performance and wide application areas.

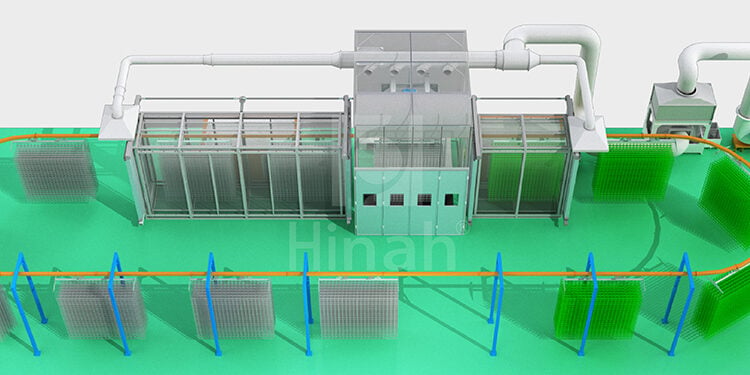

I. Introduction of Dip Tank Powder Coating Line

Dip Tank Powder Coating Line is an advanced surface treatment technology, by immersing the wire fence mesh into the powder coating, utilizing the principle of electrostatic adsorption and high temperature curing, the powder coating is firmly attached to the surface of the wire, forming a hard and durable, corrosion-resistant and weather-resistant protective layer. This type of coating not only can effectively extend the service life of wire fencing mesh, but also can enhance its aesthetics, so that it can maintain an excellent appearance in various environments.

II. Advantages of dip tank powder coating line

2.1 Strong corrosion resistance

The coating formed by the dip-tank powder coating line has excellent corrosion resistance, which can effectively resist the erosion of harsh weather conditions, chemical corrosion and salt spray. This enables the wire fencing mesh to maintain long-lasting stability in harsh environments such as humidity, acid and alkali, and is not easy to rust or fade.

2.2 High degree of weather resistance

After curing at high temperature, the powder coating forms a hard outer layer with excellent weather resistance. Whether it is hot summer or cold winter, the color and appearance of wire fencing mesh can remain stable and will not be affected by climate change.

2.3 Variety of colors and effects

The dip tank powder coating line can not only provide basic protective function for wire fencing mesh, but also provide various colors and effects of coatings according to customers’ needs, so that the fence can better integrate into the surrounding environment and meet the aesthetic requirements of different scenes.

2.4 Environmentally friendly and healthy

Compared with the traditional coating process, the dip tank powder coating line is more environmentally friendly and healthy. Powder coating does not contain organic solvents and does not produce harmful substances such as volatile organic compounds (VOC), which is not polluting to the environment and human health.

III. The application of dip tank powder coating line in wire fencing mesh

Dip tank powder coating line is widely used in the production and processing of wire fencing mesh, which gives a new quality and value to the fencing material.

3.1 Urban garden landscape

In urban parks, neighborhoods, scenic spots and other places, wire fences are often used in the creation of landscaping. Through the treatment of dip-trough powder coating line, wire fencing mesh can not only achieve corrosion resistance, weather resistance, but also can choose the color that is coordinated with the surrounding environment, adding color to the urban landscape.

3.2 Farmland protection

As an important base for food production, farmland needs to be effectively protected. The wire fencing mesh treated by the dip tank powder coating line can withstand wind and rain, and is not easy to rust, providing reliable support for the protection of farmland.

3.3 Industrial Park Safety

Industrial parks usually need to provide security for facilities, wire fencing mesh has become an important means of isolation. The dip tank powder coating line can not only enhance the durability of wire fencing mesh, but also present a professional and neat appearance, which helps to improve the overall image of the industrial park.

Conclusion

As an advanced surface treatment technology, dip tank powder coating line gives new life and value to wire fencing mesh.

Its excellent corrosion resistance, weather resistance and diversified color choices enable wire fencing mesh to show excellent performance and aesthetics in various fields.

In the future, with the continuous innovation and development of technology, the dip tank powder coating line will continue to lead the development trend of wire fencing industry, creating a better living environment for us.