Exploring NIR Curing Technology in Powder Coating Production

NIR curing technology: fast, efficient and low energy consumption

Near Infrared (NIR) curing technology is an important innovation in modern powder coating production that stands out for its high energy density and fast cure times.

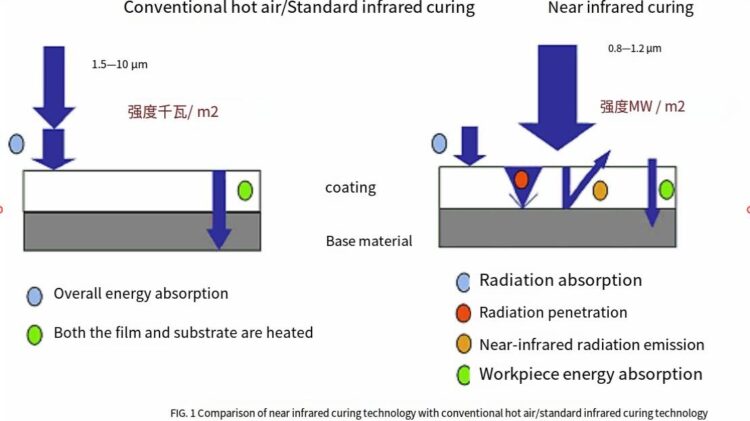

Compared to conventional hot air or standard infrared curing technologies, NIR curing technology offers a more efficient and faster curing process, resulting in increased productivity.

In this article, we will explore the principles and characteristics of NIR curing technology and its application in powder coating.

The basic principle of NIR curing technology

NIR curing technology is a curing method based on electromagnetic waves, the principle of which lies in the transmission of energy through the near infrared light to achieve rapid curing of coatings. Specifically, the technology uses near-infrared light with a very high energy density, which can be 30 to 50 times that of mid-wave infrared light. This high energy density light can fully cure a coating in a very short period of time, typically only 1 to 15 seconds.

A key feature is that in NIR technology, coating formulations often require the addition of components with polar groups, such as CaCO3, which absorb energy in the presence of NIR light to initiate the curing process. This mechanism makes NIR curing technology very different from other systems and offers several advantages.

Advantages of NIR curing technology

1. Efficient Curing Speed

One of the key reasons for the popularity of NIR curing technology is its amazing curing speed. While traditional curing methods can take much longer, NIR technology completes the entire curing process in just 1 to 15 seconds. This not only increases productivity, but also reduces the tedious waiting time in the manufacturing process.

2. Low energy consumption

Due to the rapidity of NIR curing technology, it requires relatively low energy. This is very favorable to reduce the overall energy consumption of the production process, which helps to reduce production costs and improve the environmental protection of production.

3. Low thermal shock

Unlike conventional hot air or standard infrared curing technologies, NIR technology does not expose the entire workpiece to heat during the curing process. This means that heat sensitive substrates are subjected to less thermal shock during the curing process, helping to maintain the performance and quality of the substrate.

4. Compact design

NIR curing equipment is typically compact in design and takes up less space. This provides additional flexibility in the production line and allows for more efficient use of plant space.

NIR curing technology in powder coating applications

NIR curing technology has a wide range of applications in powder coating. It can greatly improve the productivity of powder coating through a fast and efficient curing process. Below are some examples of how NIR curing technology can be used in powder coating:

1. Improvement of coating curing efficiency

NIR curing technology can significantly improve the curing efficiency of coatings and reduce the waiting time, thus increasing the overall productivity.

2. Reduced production costs

Due to low energy consumption, NIR curing technology helps to reduce production costs, including energy costs and labor costs. This makes powder coating more competitive.

3. Protection of substrate quality

The low thermal shock characteristic of NIR technology helps to protect the quality of the substrate from problems caused by excessive heating.

4. Improved environmental friendliness

Due to its low energy consumption, NIR curing technology helps to reduce carbon emissions and improve the environmental friendliness of production.

Conclusion

NIR curing technology is a revolutionary technology in the field of powder coating, which brings many benefits to powder coating production with its high efficiency, fast speed and low energy consumption.

NIR curing technology has emerged in the powder coating industry through faster curing speeds, reduced production costs, protection of substrate quality and improved environmental friendliness.

The continuous development and innovation of this technology will bring more opportunities and challenges to powder coating production in the future.