1. Adopt manual and no-line painting method:

Zhongyuan Coating Recommendation: Put the sprayed product in a dust-free environment for 5~10 minutes (this is called cold flow) and then put it into the fixed oven for baking. Generally, the ordinary one-component paint is baked. In about 15 minutes, the two-component paint should be baked for 30~45 minutes, the temperature is set to 70 degrees, and the temperature can be plus or minus 5 degrees. The product must be packaged after cooling (although the temperature of the baking is also related to the material and structure of the product. , determine the final oven temperature after verification according to the situation)

2. Painting method of manual production line and painting line with tunnel oven:

Central Plains Painting Suggestion: The oven on the assembly line is equipped with multi-section temperature control. The temperature of 1~3 meters in front of the assembly line should not have the furnace temperature. The temperature of each subsequent oven is set from bottom to high, and each section can be increased by 5~10 degrees. Since the oven on the assembly line is not completely enclosed, the temperature of the oven should be appropriately 10-20 degrees higher than the temperature of the fixed oven, depending on the product.

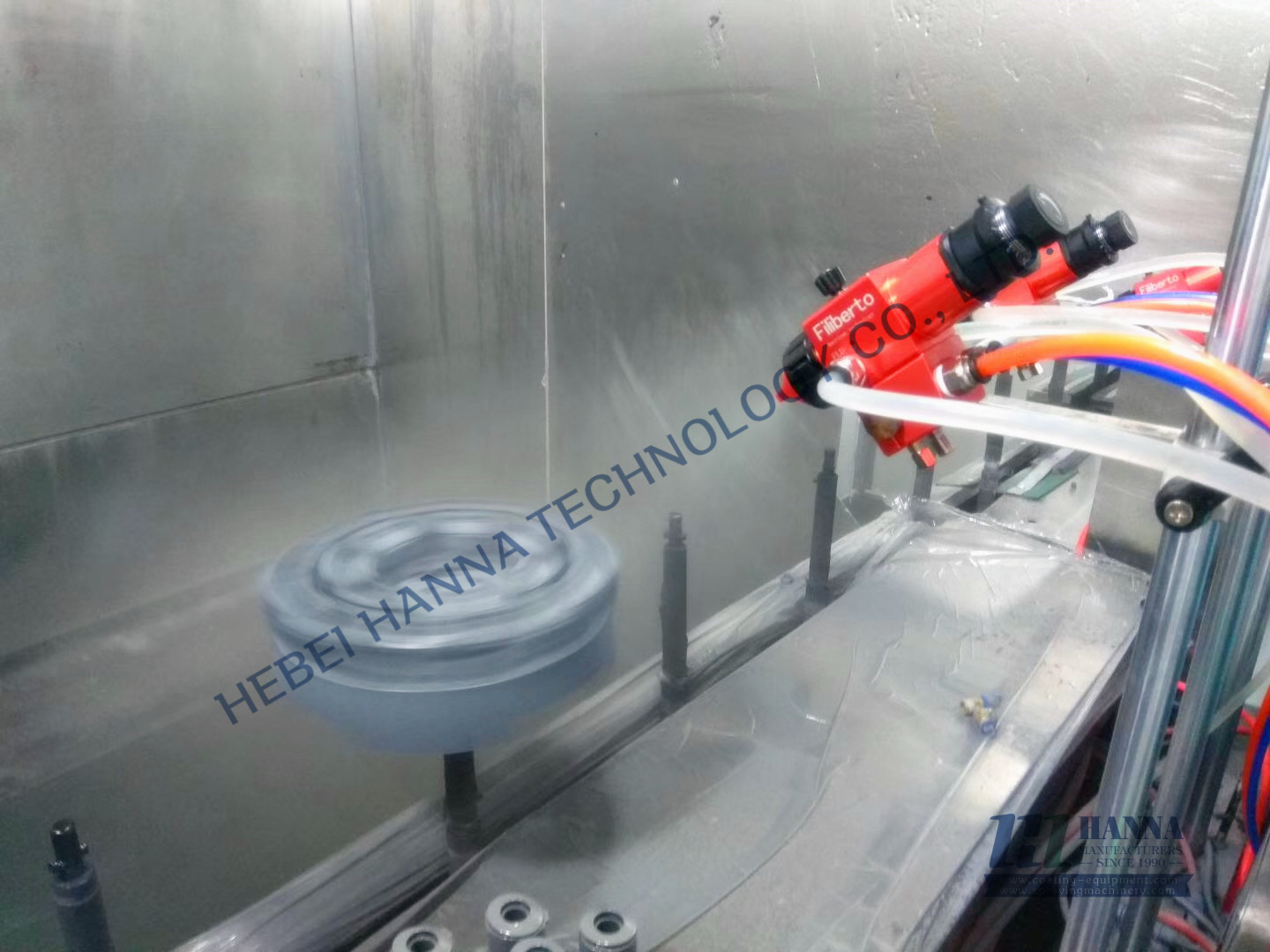

3. Painting method using automatic painting production line:

Zhongyuan painting recommendation: When designing the line body (the line body is generally adjustable from 1 to 6 meters), the line speed of 5 meters per minute should be used to set the line speed of no less than 5 minutes. The temperature control method is also controlled by a multi-section oven.

Want to know more about powder coating equipment, please contact us.

we web:www.powderspraymachine.com

email:sales@powderspraymachine.com