Description:

The electrophoretic paint production line (e-coating line) is a type of equipment used in the automated painting process and is widely used in the production of automobiles, home appliances, construction and furniture. Electrophoretic paint is an anti-corrosion, anti-rust, anti-corrosion and anti-pollution coating that improves the appearance and service life of products. The following is a brief description of the equipment and role of the electrophoretic paint production line.

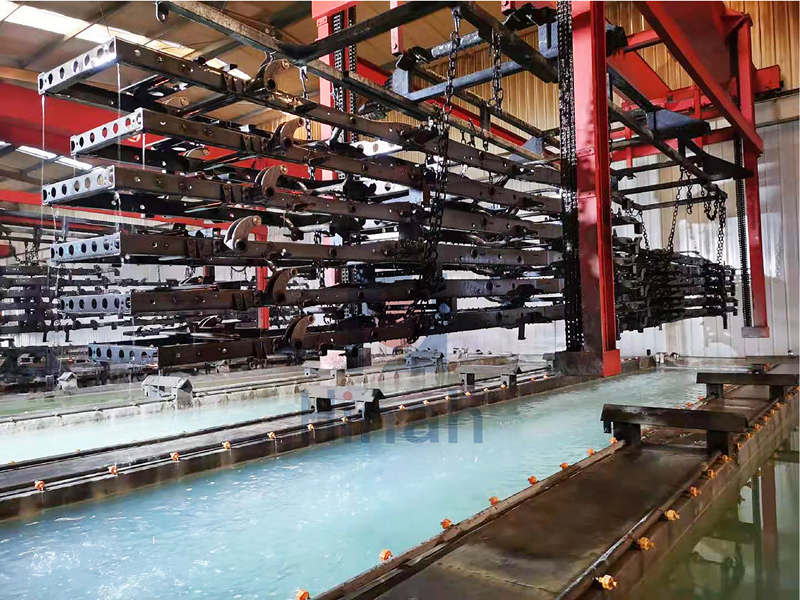

Electrophoresis tank:

The electrophoresis tank is one of the core equipment of the painting line and is usually made of steel or polyethylene material. The bath is usually filled with electrophoresis fluid, which is used to deposit the paint evenly onto the surface of the workpiece by the action of the electric field.

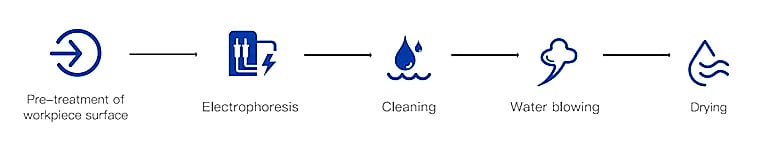

Pre-treatment equipment:

The pre-treatment equipment mainly includes processes such as oil removal, rust removal and phosphating, through which dirt and oxides on the surface of the workpiece can be removed, making it easier for the surface of the workpiece to bond with the paint.

Washing equipment:

In the electrophoretic paint production line, the paint needs to be washed before it is applied to the surface of the workpiece. The washing equipment usually has several stations to clean and rinse the surface of the workpiece by spraying and soaking.

Ovens:

Ovens are used to cure the electrophoretic coating and to improve the wear and corrosion resistance of the coating. Ovens usually consist of heaters, fans, exhaust ducts etc.

Cooling equipment:

Cooling equipment is used to cool the workpiece to prevent problems such as deformation or discolouration of the coating after drying.

Automatic conveying equipment:

Automatic conveying equipment is used to automatically convey workpieces to improve production efficiency and coating quality.

The role of the electrophoretic paint production line is to deposit the paint evenly on the surface of the workpiece to form a layer of anti-corrosion, anti-rust, anti-corrosion and anti-pollution electrophoretic coating.

The thickness and quality of the coating can be controlled by adjusting the parameters of the electrophoretic paint production line.

With the electrophoretic paint production line, the quality and appearance of the product can be improved, the service life of the product can be extended and production costs and environmental pollution can be reduced.

Details

Components of electrophoresis equipment

Electrophoretic coating involves immersing the products to be coated in water-soluble paint as an anode (anodic electrophoresis) and setting up a corresponding cathode to pass a direct current between the two electrodes.

The physical and chemical effects of the current cause the paint to be uniformly coated.

◆Components of electrophoresis equipment:

① Tank body — ② Stirring circulation system — ③ Electrode device — ④ Perature adjustment device — ⑤ Paint supply device — ⑥ Ultrafiltration device — ⑦ Ventilation device — ⑧ Power supply device — ⑨ Washing device after e-coating — ⑩ Paint storage device.

◆ Equipment operation mode:

The whole set of equipment is fully automated.

◆ Program control mode:

Imported relay, time relay control PLC+touch screen control.

◆ Performance characteristics:

1, High degree of automation.

2, Rreliable operation.

3, Product out high production efficiency.

4, Consistent mass production of coatings.

5, Precise controllable coating thickness.

Features

Product Features

1, High paint utilization

Compared with other spraying methods, the utilization rate of paint can be higher than 95%.

2, Good permeability and uniform coating film

The electrophoretic bath liquid has high electrical conductivity, and the paint particles can be actively swept and deposited on the painted object.

Even and smooth paint film can be obtained at the welding seam of the tendon plate, etc.

3, Fast speed and strong adhesion

The construction speed of electrophoretic coating is fast, mechanized and automated continuous operation can be realized, reducing labor intensity, uniform paint film and strong adhesion.

4, Rust resistance, corrosion resistance

The paint film dried after electrophoresis has excellent adhesion, and its properties of rust resistance, corrosion resistance and weather resistance are better than those of ordinary paints and general painting methods.

5, Safe and environmental protection green painting

The utilization rate of paint is as high as 90%-95%, and because electrophoretic paint uses water as solvent, it has the advantages of non-combustibility, non-toxicity and easy operation.

6, Good drying spreading property

The coating film after electrophoretic washing is dry, and it is not stained by hand, and the drying time is short, so it can go into drying directly.

Online Inquiry

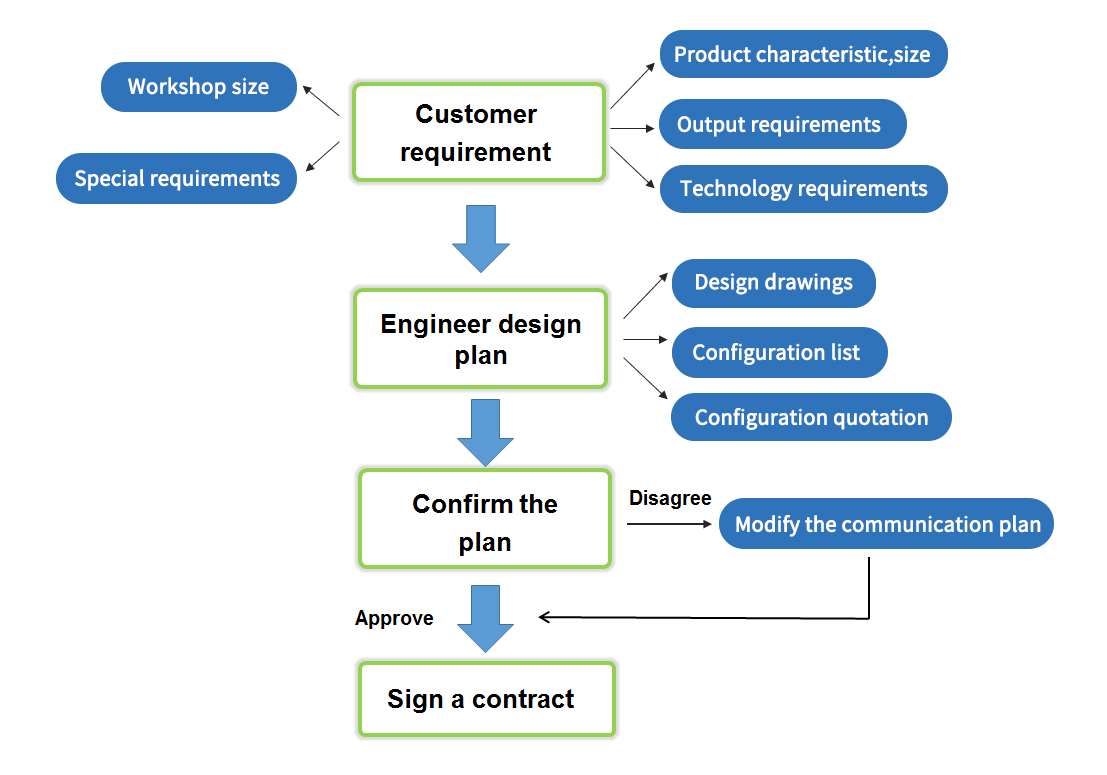

If you want to custom made any powder coating line, Pls tell us the following specifications:

1.The material of your workpiece.

2.The size of your workpiece .

3.The weight of your workpiece.

4.The output of your workpiece (one day=8hours,one month=30days).

5.The heating power you prefer: electric, gas, diesel, or coal.

6.The size of your factory (length, width and height).

We could make the design according customer’s requirements. Pls contact with me and we will give you the quick reply.

Order Process